Signs Your Forklift Batteries Need Replacement

Introduction

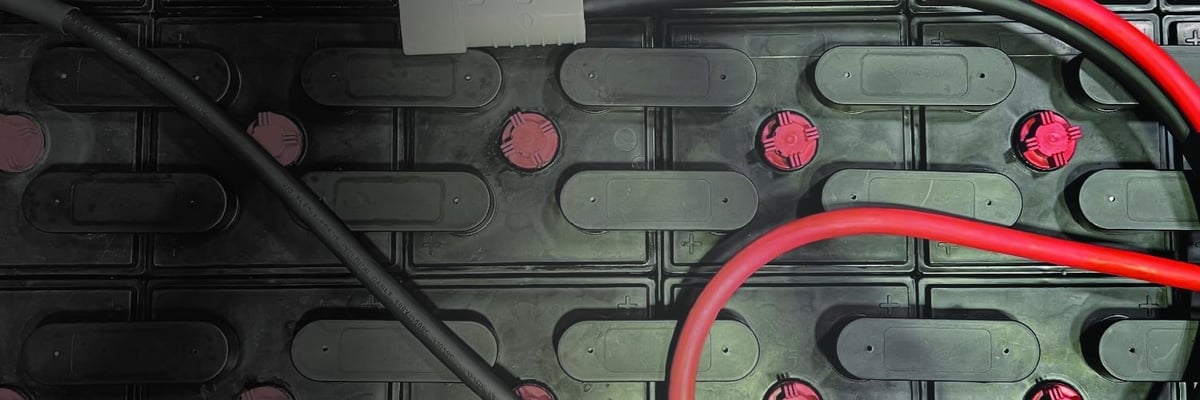

When it comes to operating a forklift, the lifeblood of your machinery is undoubtedly its batteries. As a crucial component in maintaining productivity and ensuring safety, forklift batteries require regular attention and maintenance. Recognizing when these batteries need replacement can save you from costly downtime and potential accidents. So, how can you tell if your forklift batteries are on their last legs? In this article, we will explore the signs your forklift batteries need replacement, so you can keep your operations running smoothly.

Signs Your Forklift Batteries Need Replacement

Identifying the signs that indicate forklift batteries need replacing is essential for any warehouse or manufacturing facility. Neglecting battery issues can lead to decreased efficiency, increased costs, and even safety hazards.

1. Decreased Performance

Have you noticed a drop in the lifting capacity of your forklift? That’s usually one of the first signs something's amiss with your battery. Over time, forklift batteries lose their ability to hold a charge effectively. If your equipment is struggling to lift loads it once 24 volt flat plate forklift batteries handled with ease, it's a clear indicator that the battery might be nearing its expiration date.

- Symptoms of Decreased Performance:

- Longer charging times

- Shorter run times between charges

- Difficulty in reaching full lift capacity

What should you do about it? First lead-acid forklift batteries off, monitor how long it takes for the battery to recharge and observe if there’s a notable increase in time. Keep track of how long your forklift runs before needing another charge; typically, an efficient battery will provide several hours of operation before requiring a recharge.

2. Swelling or Bulging Cases

Another visible sign that your forklift batteries may need replacement is physical damage such as swelling or bulging cases. This often occurs due to overcharging or internal damage within the battery cells.

- Why does this happen?

- Overcharging heats up the electrolyte inside the battery.

- Internal pressure builds up, causing deformation.

What should you look for?

- Any noticeable warping or bulging on the surface of the battery case

- Leakage of acid or fluid around the terminals

Is it safe to operate? Absolutely not! If you observe any signs of swelling or leakage, stop using that forklift immediately and consult an expert for further inspection.

3. Unusual Sounds

Do you hear strange noises when operating your forklift? If so, that could be another red flag indicating that your forklift batteries are due for replacement.

- Common sounds to listen for:

- Hissing: This could be gas escaping from overcharged batteries.

- Gurgling: This indicates that there may be excessive heat or bubbling within cells.

Ignoring these sounds can lead to more severe problems down the line, including complete battery failure or even fire hazards!

Understanding Forklift Battery Lifespan

Factors Affecting Lifespan

Forklift batteries typically last between four to six years under optimal conditions; however, various factors can affect their longevity:

How to Extend Battery Life

If you're looking to maximize the lifespan of your forklift batteries, consider implementing some best practices:

- Regularly maintain and clean terminals.

- Monitor charge cycles closely.

- Store forklifts in temperature-controlled environments when not in use.

Signs Your Forklift Batteries Need Replacement: Monitoring Health

4. Corrosion on Terminals

Are there white powdery substances accumulating around your battery terminals? That corrosion is not just unsightly—it’s also telling you something vital about your battery's health.

- What causes corrosion?

- Electrolyte leaks

- Poor connections

Corrosion hampers electrical flow and leads to inefficient performance. It's crucial to clean corroded terminals promptly; otherwise, it could lead to bigger problems down the road.

5. Age and Usage History

How old are those batteries anyway? The age of a battery is a strong determining factor in its effectiveness and reliability.

- A well-maintained lead-acid battery may serve up to six years while lithium-ion types could last longer but still have a finite life expectancy.

Keep track of each battery's usage history—including daily operational hours—to better assess when it might be time for replacements.

6. Warning Lights on Control Panel

Most modern forklifts have built-in diagnostic systems that alert operators through warning lights on control panels when there's an issue with power supply—this includes problems related specifically to batteries.

If you see a flashing light indicating low voltage or other warnings tied directly to power sources:

- Take immediate action by checking both fluid levels and overall condition.

Ignoring these signals may jeopardize not only efficiency but also worker safety!

FAQs About Forklift Batteries Replacement

How often should I replace my forklift batteries? Typically every four to six years unless factors like misuse shorten their lifespan.

Can I replace individual cells in my forklift battery? While it's technically possible, it's often better practice—and safer—to replace entire units.

What are some common types of forklift batteries? The most common types include lead-acid and lithium-ion.

Is it safe to charge batteries overnight? Yes, but ensure they’re not overcharged; invest in smart chargers if possible.

How do I properly dispose of old fork-lift batteries? Contact local waste management facilities specializing in hazardous materials.

Can weather affect my forklift battery performance? Absolutely! Temperature extremes can significantly impact efficiency and longevity.

Conclusion

Recognizing the signs your forklift batteries need replacement is paramount for maintaining operational efficiency and ensuring workplace safety. From decreased performance metrics and physical deformities like swelling cases to unusual noises and corrosion at terminals—each symptom offers valuable insights into your equipment’s health.

Regular monitoring combined with effective maintenance practices 12 volt flat plate forklift batteries will not only extend battery life but also save costs associated with premature replacements and downtime caused by malfunctioning 36 volt flat plate forklift batteries equipment.

By staying vigilant about these indicators, you'll ensure smooth operations day-in and day-out while keeping everyone safe around those heavy machines! Remember: A proactive approach today can prevent costly repercussions tomorrow!