How to Choose the Right Forklift Batteries

Choosing the right forklift batteries is crucial for businesses that rely on forklift operations. The choice can affect not only productivity but also maintenance costs and overall operational efficiency. In this article, we’ll explore everything you need to know about selecting the appropriate forklift batteries for your specific needs.

Understanding Forklift Batteries

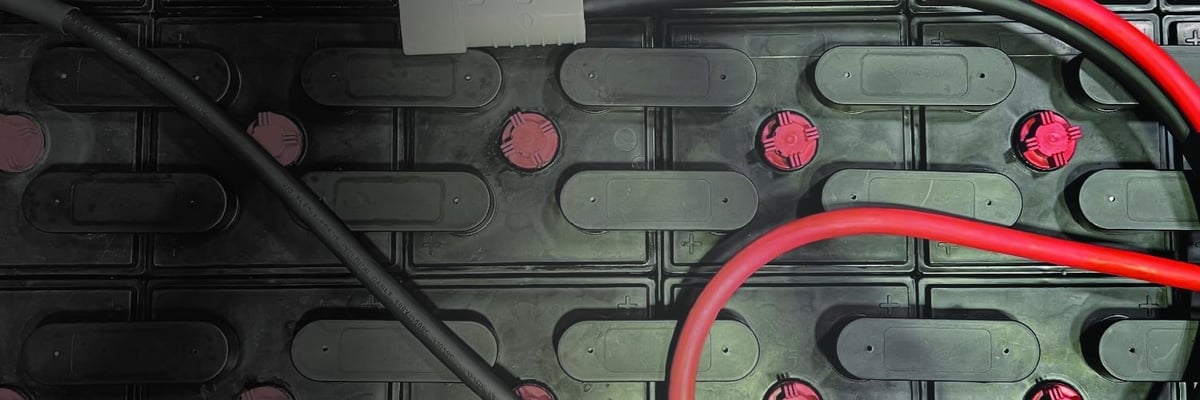

Forklift batteries are the powerhouse behind 24 volt flat plate forklift batteries electric forklifts, serving as the primary energy source that enables these machines to function effectively. But how do they work? In essence, forklift batteries convert chemical energy into electrical energy, which is then used to power the motor of the forklift.

Types of Forklift Batteries

When it comes to forklift batteries, there are several types available. The most common include:

- The traditional choice for many businesses.

- Known for their durability and relatively low cost.

- Require regular maintenance, such as water filling.

- A newer technology gaining popularity.

- Offer faster charging times and require less maintenance.

- Higher upfront cost but can lead to savings in long-term operational costs.

- Less common but still used in certain applications.

- Known for their longevity and performance in extreme temperatures.

- Higher initial cost with a longer lifespan compared to lead-acid.

- Maintenance-free options that use gel or absorbed glass mat technology.

- Ideal for environments where spills could be hazardous.

Factors to Consider When Choosing Forklift Batteries

So, how do you decide which type of battery 36 volt flat plate forklift batteries is right for your operation? Here are some key factors to consider:

Operating Environment

Is your warehouse climate-controlled or exposed to extreme temperatures? Lithium-ion batteries may be more suitable in fluctuating conditions since they perform well in various environments.

Usage Patterns

Cost vs. Longevity

Are you looking at short-term savings or long-term investments? While lead-acid batteries are cheaper upfront, lithium-ion batteries often provide better ROI due to their longevity and reduced maintenance requirements.

Maintenance Requirements

Do you have resources dedicated to battery maintenance? If not, consider maintenance-free options like lithium-ion or AGM batteries to save time and labor costs down the line.

How to Choose the Right Forklift Batteries

Choosing the right forklift battery isn’t just a matter of picking one off the shelf; it’s about aligning your choice with your specific operational needs. Here’s a comprehensive guide on how you 80 volt flat plate forklift batteries can make an informed decision:

1. Assess Your Operational Needs

Before you even start shopping around for forklift batteries, it's crucial to assess your operational needs comprehensively:

- Daily Usage: How many hours a day will your forklifts be running?

- Load Capacity: What is the weight of goods you're moving?

- Cycle Times: How quickly do you need the forklifts charged between shifts?

By answering these questions, you'll have a clearer picture of what kind of battery capacity and runtime you'll need from your forklift batteries.

2. Evaluate Battery Specifications

Once you've established your needs, it's time to dive into specifications:

- Voltage Ratings: Most electric forklifts operate on either 24V or 36V systems; make sure you choose a battery compatible with your machine.

- Amp-Hours (Ah): This rating indicates how much energy a battery can deliver over time. More amp-hours mean longer run times but also larger physical sizes.

- Weight: Heavier batteries can add stability but may also impact lift capacity; ensure you're within safe operating limits for both weight and performance.

3. Look Into Charging Options

The availability of charging stations can significantly influence your decision:

- If fast turnover is essential, investing in rapid chargers could benefit lithium-ion users greatly.

- Conversely, if you’re using lead-acid batteries, ensure there's adequate space and time allocated for watering and equalizing charges during downtime periods.

4. Consider Long-Term Costs

While upfront costs are always tempting when making a purchase decision, don’t forget about long-term implications:

- Maintenance Costs: Lead-acid requires regular checks—water levels must be monitored frequently—which can add labor costs over time.

- Replacement Frequency: Lithium-ion typically lasts longer than other types; therefore, despite its higher upfront cost, it may prove cheaper over time due to fewer replacements needed.

Frequently Asked Questions (FAQs)

1. What type of battery is best for my electric forklift?

It depends on factors like daily usage patterns and environmental conditions; lithium-ion offers lower maintenance while lead-acid provides affordability upfront.

2. Can I use any battery brand with my forklift?

No! Always refer to manufacturer specifications regarding compatible battery brands and models for safety reasons.

3. How often should I maintain my lead-acid forklift batteries?

Typically every 12 volt flat plate forklift batteries 5–10 charge cycles depending on usage; check water levels regularly as part of routine maintenance practice.

4. What’s the average lifespan of a lithium-ion forklift battery?

On average, lithium-ion batteries last between 5–10 years compared with 3–5 years for lead-acid counterparts under proper usage conditions.

5. Are there environmental considerations when disposing of old forklift batteries?

Absolutely! Most regions have regulations regarding battery disposal due to toxic materials—always consult local guidelines before disposal!

6. Do lithium-ion batteries require special chargers?

Yes! They often require specific chargers designed for lithium technology capable of handling fast charging rates without damaging cells.

Conclusion: Make an Informed Choice

Choosing the right forklift batteries involves considering various factors including operational needs, financial implications, and technical specifications—all pointing toward sustainable choices that enhance productivity while keeping costs manageable over time.

Your choice shouldn’t just be about what fits today; think ahead! With advancements in technology like lithium-ion rapidly becoming mainstream alternatives against conventional methods—there's never been a better time than now!

By following this guide on How to Choose the Right Forklift Batteries, you're well-equipped not just with knowledge but also actionable insights—a winning combination that guarantees efficiency in your operations!