Sustainable Innovations in Industrial Batteries

In a world increasingly focused on sustainability, the quest for greener energy solutions has taken 72 volt flat plate forklift batteries center stage. One crucial area of focus is industrial batteries, which power everything from forklifts to large machinery. With advancements in technology and a surge in environmental awareness, the landscape of industrial batteries is rapidly evolving. This article dives into sustainable innovations in industrial batteries and how they are transforming industries while reducing environmental impact.

Sustainable Innovations in Industrial Batteries

The term "sustainable innovations" refers to new technologies or practices that not only enhance performance but also minimize ecological footprints. In the context of industrial batteries, this involves developing materials and processes that reduce waste, increase efficiency, and lower harmful emissions.

Revolutionizing Forklift Batteries for Sustainability

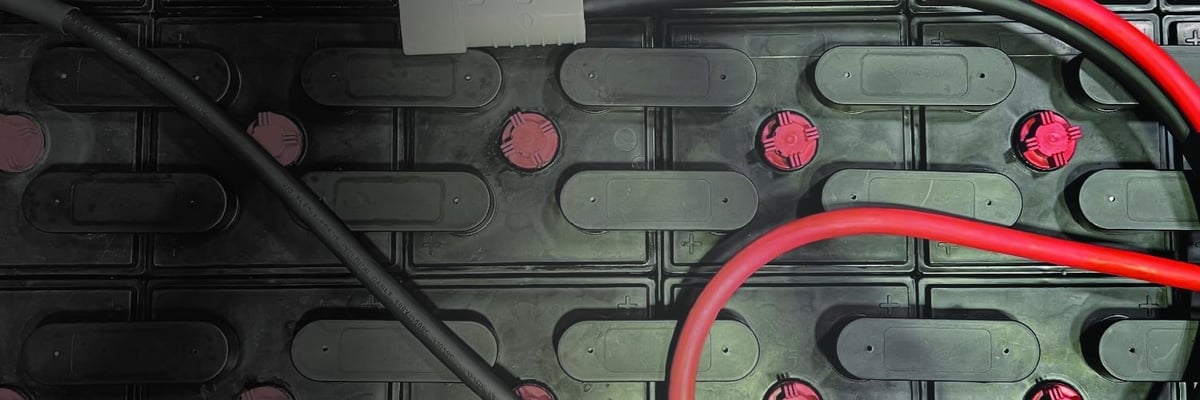

Forklifts are essential in warehouses and factories, but they often rely on traditional lead-acid batteries that are heavy, inefficient, and potentially hazardous to the environment. Recent innovations have led to the development of lithium-ion forklift batteries that offer several advantages.

Longer Lifespan: Lithium-ion batteries can last up to twice as long as their lead-acid counterparts. This longevity reduces the frequency of battery replacements and ultimately decreases waste.

Energy Efficiency: These batteries charge faster and discharge more efficiently than traditional options. This means less energy consumption overall, leading to lower operational costs—an appealing prospect for businesses looking to cut expenses.

Reduced Emissions: By transitioning to lithium-ion technology, companies can significantly decrease their carbon footprint. Fewer battery replacements mean less mining for raw materials like lead and sulfuric acid.

Safety Improvements: Lithium-ion forklift batteries come equipped with advanced safety features that help mitigate risks associated with overheating or chemical leaks.

As companies adopt these innovative battery solutions, they not only improve their bottom line but also contribute positively to environmental conservation efforts.

Emerging Technologies in Industrial Battery Recycling

A critical aspect of sustainable innovations in industrial batteries lies in recycling technologies. As industries transition toward greener alternatives, understanding how to properly recycle old or depleted batteries becomes paramount.

Battery Recycling Processes

-

Mechanical Separation: In this method, used batteries are mechanically broken down into smaller components. Metals like lithium, cobalt, nickel, and copper can then be separated for reuse.

-

Hydrometallurgical Techniques: This process uses aqueous solutions to extract valuable metals from battery components. It has gained traction because it can recover nearly 95% of metals without causing significant pollution.

-

Pyrometallurgical Techniques: Though less environmentally friendly due to high energy demands and emissions produced during processing, pyrometallurgy remains relevant for specific types of batteries.

The Importance of Recycling Initiatives

The need for effective recycling methods cannot be overstated:

- It minimizes the extraction of new raw materials, therefore conserving natural resources.

- It reduces landfill waste associated with discarded batteries.

- It lowers greenhouse gas emissions by recycling instead of producing new battery components from scratch.

By investing in robust recycling infrastructure and leveraging state-of-the-art technologies, industries can pave the way for a circular economy around industrial batteries—one where products are reused rather than disposed of after their lifecycle ends.

Future Trends in Sustainable Battery Technology

As we look ahead, several trends are likely to shape the future of sustainable innovations in industrial batteries:

Solid-State Batteries: A Game Changer?

Solid-state battery technology is emerging as a frontrunner when it comes to sustainable innovations. Unlike conventional lithium-ion batteries that use liquid electrolytes, solid-state versions employ solid electrolytes which enhance safety while improving energy density. Here’s what makes them so promising:

-

Higher Energy Density: Solid-state batteries can store more energy per unit volume than traditional options; this means longer-lasting power with reduced weight—a crucial factor for portable equipment like forklifts.

-

Improved Safety: The absence of flammable liquids drastically decreases risks related to fires or leaks during operation.

-

Extended Lifecycle: Solid-state designs often exhibit longer lifespans due to reduced wear over time compared to liquid electrolyte systems.

Bio-Based Materials in Battery Production

Another exciting trend is the incorporation of bio-based materials into battery production:

Natural Graphene: Derived from organic sources such as algae or plant matter, natural graphene offers excellent conductivity while being environmentally friendly.

Biodegradable Components: Researchers are exploring ways to develop biodegradable electrodes that break down naturally after disposal without harming ecosystems.

By harnessing renewable resources for manufacturing processes, industries can significantly diminish their reliance on finite fossil fuels while promoting sustainability across supply chains.

FAQs about Sustainable Innovations in Industrial Batteries

- Traditional forklift batteries are typically lead-acid based; however, modern options increasingly utilize lithium-ion technology due to its efficiency and longevity benefits.

- Signs include diminished lift capacity, longer charging times than usual, or visible corrosion around terminals indicating internal damage.

- Discarding an un-recycled battery contributes significantly towards landfill waste and increases environmental hazards through toxic material leakage into soil or water supplies.

- While still largely experimental at this stage compared with traditional lithium-ion models; many manufacturers anticipate commercial availability within just a few years as production techniques improve!

- Absolutely! Advances have made it possible for reclaimed metals from recycled products (like old car or phone batteries) to be repurposed efficiently into new ones—thereby closing resource loops!

- Many governments worldwide offer incentives or grants aimed at encouraging research & development efforts focused on advancing green tech initiatives—including those related specifically towards cleaner energy storage solutions!

Conclusion

In summary, sustainable innovations in industrial batteries represent an intersection between technological advancement and environmental responsibility. The shift from traditional lead-acid systems toward more efficient alternatives like lithium-ion—and eventually solid-state technologies—demonstrates a commitment towards reducing carbon footprints while enhancing operational efficiency across sectors reliant upon heavy machinery such as forklifts or other warehouse logistics equipment!

As industries continue embracing these changes alongside effective recycling methods tailored 36 volt flat plate forklift batteries specifically towards maximizing recovery rates; we move ever closer toward achieving balanced progress—both economically viable yet ecologically sound!