Selecting Chargers for Forklift Batteries

Forklifts are essential in various industries, providing the muscle needed to transport heavy loads efficiently. However, the heart of any forklift operation lies in its battery. Choosing the right charger for forklift batteries is crucial for maximizing performance, extending battery life, and ensuring safety on the job. This article delves into the intricacies of selecting chargers for forklift batteries, helping you make informed decisions that enhance productivity and reliability.

Selecting Chargers for Forklift Batteries

When it comes to selecting chargers for forklift batteries, understanding your specific requirements is paramount. Different types of forklift batteries require different charging methods and equipment. Here’s a 12 volt flat plate forklift batteries breakdown of what to consider when choosing a charger:

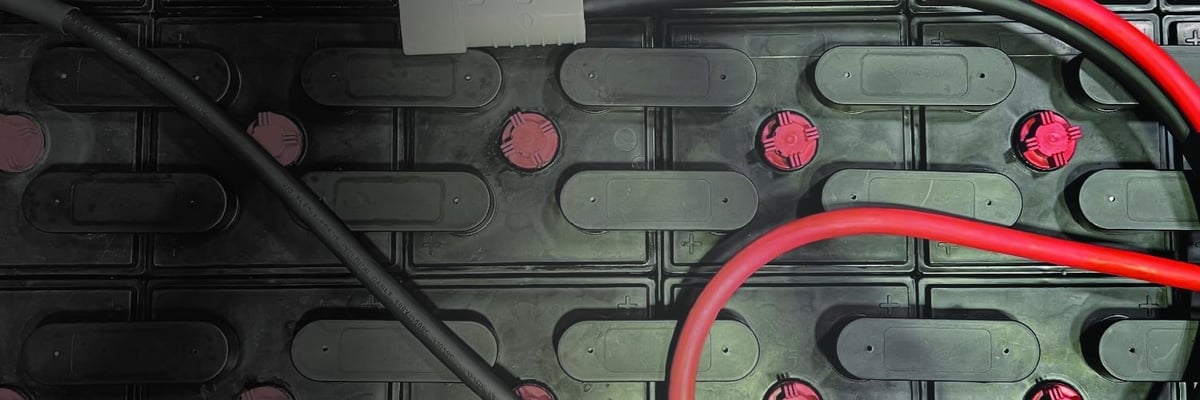

Types of Forklift Batteries

Lead-Acid Batteries: These are the most common type used in forklifts due to their cost-effectiveness and reliability. Lead-acid batteries come in two variations: flooded and sealed (AGM or gel). Each has specific charging needs.

Lithium-Ion Batteries: Gaining popularity due to their efficiency and lower maintenance requirements, lithium-ion batteries offer fast charging capabilities but may require specialized chargers.

Nickel-Cadmium Batteries: While less common today, these batteries are still found in certain applications. They have unique charging requirements that differ from lead-acid and lithium-ion types.

Charger Specifications

Once you’ve identified the type of battery your forklift uses, the next step is to consider the specifications of the charger:

-

Voltage: Ensure that the charger's voltage matches that of your battery system; mismatched voltages can lead to inefficiencies or damage.

-

Amperage: The amperage rating determines how quickly your battery will charge. A higher amperage means faster charging but can also generate more heat.

-

Charge Cycle Type: There are different charge cycle types like constant current/constant voltage (CC/CV) or multi-stage charging systems that optimize battery health by adjusting charging rates at different stages.

Smart Charging Technology

Modern fork truck chargers often come equipped with smart technology that allows them to monitor battery condition and adjust charge cycles accordingly. This not only improves efficiency but also prolongs battery life by preventing overcharging—a common issue with older chargers.

Benefits of Smart Chargers

-

Efficiency: Smart chargers can reduce energy consumption by optimizing charge cycles based on real-time data.

-

Battery Health Monitoring: Many smart chargers provide insights into battery health, indicating when maintenance is needed or when it's time for a replacement.

-

Auto Shut-off Features: To prevent overcharging, many smart models will automatically shut off once a full charge is reached.

Factors Influencing Charger Selection

Choosing a charger isn’t just about matching specs; several factors should influence your decision-making process:

Operational Environment

The environment where forklifts operate plays a significant role in determining which type of charger to select:

-

Indoor vs Outdoor Use: Indoor environments typically have stable temperature conditions; however, outdoor environments might expose chargers to extreme temperatures and moisture levels—consider weather-resistant options if this applies.

-

Frequency of Use: If your forklifts operate continuously throughout shifts, investing in high-quality fast chargers may be necessary to minimize downtime between shifts.

Battery Capacity and Size

Understanding the capacity (measured in amp-hours) and size of your forklift batteries ensures you choose a compatible charger. Chargers must be rated appropriately for the amp-hour capacity of your batteries to ensure efficient charging without damaging them.

Example Table

| Battery Type | Voltage | Typical Amperage | Charge Time | |--------------------|---------|-------------------|--------------| | Lead-Acid | 12V/24V | 15A - 90A | 6 - 8 hours | | Lithium-Ion | 24V | 30A - 100A | 1 - 3 hours | | Nickel-Cadmium | 12V | 10A - 50A | Varies |

Cost Considerations

While it may be tempting to opt for cheaper options, remember that investing in quality can save costs down the line through reduced maintenance needs and improved energy efficiency. Always weigh initial costs against potential long-term savings.

Best Practices for Charging Forklift Batteries

Consistent Charging Schedule: Establishing a routine can help maximize performance while minimizing wear on both the charger and battery.

Regular Maintenance Checks: Periodically inspect both batteries and chargers for signs of corrosion or damage.

Train Operators Properly: Ensure all operators understand how to use the charging systems correctly as improper use can lead to safety hazards or equipment damage.

Monitor Temperature Levels: Keep an eye on temperature during charging—overheating can lead to irreversible damage.

FAQs About Selecting Chargers for Forklift Batteries

What is the best type of charger for lead-acid forklift batteries?

The best type would be an automatic multi-stage charger designed specifically for lead-acid technology, featuring temperature compensation features to prevent overheating during hot weather.

Can I use any charger on my lithium-ion forklift battery?

No! Lithium-ion batteries require specific chargers designed with smart technology features tailored exclusively for their chemistry due to their unique characteristics regarding voltage levels and thermal management.

How often should I charge my forklift's battery?

You should charge your forklift's battery regularly 80 volt flat plate forklift batteries after each shift or whenever it reaches approximately 20% discharge level—not letting it drop too low helps maintain its lifespan!

Are there portable chargers available?

Yes! Many manufacturers produce compact portable options suitable for quick top-offs during busy operations without needing extensive setups or downtime!

What happens if I overcharge my forklift battery?

Overcharging can cause excessive lead-acid forklift batteries heat buildup which might result in electrolyte loss from lead-acid cells leading directly towards premature failure!

Is it safe to leave my charger plugged in overnight?

It depends on whether you're using an automatic smart charger—these devices will regulate themselves preventing overcharging! However always check manufacturer guidelines before doing so!

Conclusion

Selecting chargers for forklift batteries involves understanding various factors such as battery types, specifications, environmental conditions, and operational needs. By taking these elements into account along with adopting best practices like regular maintenance checks and training operators properly—you’ll ensure that your forklifts operate at peak performance while maximizing both safety & longevity! Investing time upfront pays dividends down-the-line as efficient 18 volt flat plate forklift batteries machines run smoother yielding greater profits overall!