Industrial Batteries Standards to Know

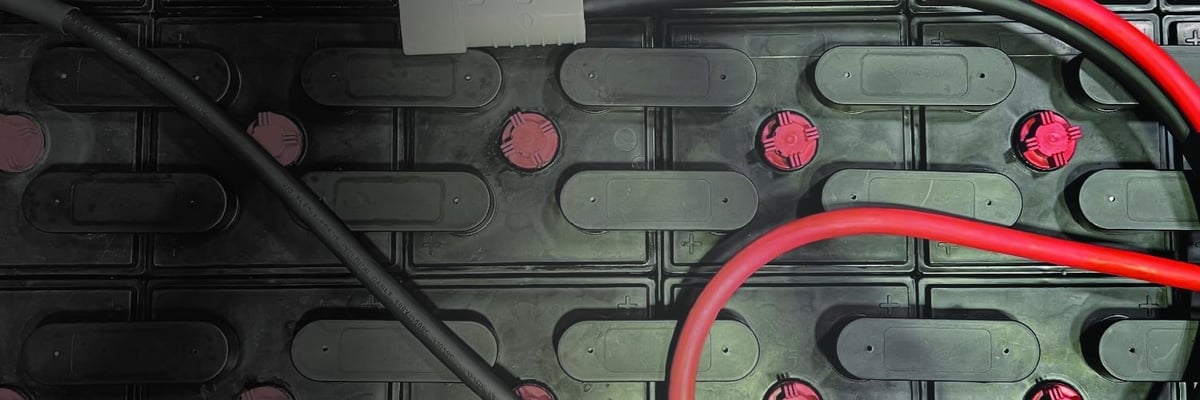

When it comes to powering industries, the importance of reliable and efficient battery systems cannot be overstated. With the surge in demand for energy storage solutions, especially in sectors like warehousing and logistics, forklift batteries have emerged as a critical component. Understanding the standards governing these industrial batteries is crucial for ensuring safety, efficiency, and compliance. In this article, we will delve into various industrial battery standards that every business should know.

Industrial Batteries Standards to Know

Industrial batteries are subject to a variety of standards designed to ensure their safety, performance, and reliability. These standards vary by region and application but generally include 18 volt flat plate forklift batteries guidelines 24 volt flat plate forklift batteries on manufacturing practices, safety measures, testing protocols, and environmental considerations.

1. ANSI/NEMA Standards

The American National Standards 80 volt flat plate forklift batteries Institute (ANSI) along with the National Electrical Manufacturers Association (NEMA) provides comprehensive guidelines concerning electrical equipment including industrial batteries.

- ANSI C18: This standard governs portable rechargeable batteries and is particularly relevant for lithium-ion technologies commonly used in forklift batteries.

- NEMA 250: This standard deals with enclosures for electrical equipment which is crucial when considering battery installations in harsh environments.

Why Are They Important?

Adhering to ANSI/NEMA standards ensures that the forklift batteries meet safety requirements that protect both workers and equipment from potential hazards. Compliance with these guidelines reduces risks associated with overheating, short-circuiting, or even catastrophic failures.

2. ISO Standards

The International Organization for Standardization (ISO) sets international benchmarks that affect various aspects of industrial battery production and usage.

- ISO 9001: Focused on quality management systems, this standard helps manufacturers maintain high-quality processes throughout the production chain.

- ISO 14001: This environmental management standard ensures that companies minimize their ecological footprint during battery production and disposal.

How Do They Impact Forklift Batteries?

36 volt flat plate forklift batteries For businesses utilizing forklift batteries, adherence to ISO standards can significantly enhance operational efficiency while ensuring compliance with environmental regulations. Choosing suppliers who meet these standards often translates into better product quality and reliability.

3. UL Certification

Underwriters Laboratories (UL) provides certification services for electrical devices including industrial batteries.

- UL 1989: This standard focuses specifically on the safety of lead-acid storage batteries.

- UL 2054: Pertaining to household and commercial batteries but applicable to larger battery systems used in industrial settings as well.

What Does UL Certification Mean?

Having UL certification means that a battery has undergone rigorous testing for safety under various conditions. For companies using forklift batteries, this certification offers peace of mind regarding the safe operation of their equipment.

4. IEC Standards

The International Electrotechnical Commission (IEC) is responsible for global electrical standards including those relevant to industrial batteries.

- IEC 62133: Deals with the safety requirements for portable sealed secondary cells and batteries.

- IEC 62619: Focuses on the safety requirements for large-format lithium-ion cells used in stationary applications which can also be utilized in some types of forklifts.

Why Consider IEC Standards?

5. Battery Recycling Standards

As sustainability becomes increasingly important in industry practices, understanding battery recycling standards is vital:

- RCRA (Resource Conservation and Recovery Act): In the U.S., this act regulates hazardous waste management including lead-acid batteries.

- WEEE Directive (Waste Electrical and Electronic Equipment): In Europe, this directive mandates proper disposal methods for electronic waste including industrial batteries.

What’s at Stake?

Failure to comply with recycling standards could result in hefty fines or legal repercussions while contributing negatively to environmental degradation—the very opposite of what companies aim to achieve today.

Common FAQs About Industrial Battery Standards

- Compliance ensures safer operations, enhances product reliability, improves marketability, and helps avoid legal issues related to safety violations or improper waste disposal.

- Yes! While many general electrical standards apply to all types of industrial batteries, specific guidelines from organizations like ANSI/NEMA focus on aspects pertinent specifically to forklift applications.

- You can request documentation proving compliance or certifications directly from your supplier; reputable companies will readily provide this information.

- No! Each country may have its own regulations based on local needs; however, many adhere closely to ISO or IEC guidelines which are recognized internationally.

- Companies may face penalties ranging from fines to mandatory recalls or changes in operational procedures until compliance is achieved again.

- Industry standards are regularly reviewed—typically every few years—to adapt new technologies or address emerging safety concerns so staying updated is crucial!

Conclusion

Understanding Industrial Batteries Standards to Know is essential not just for compliance but also for fostering a culture of safety within your organization while optimizing operations involving forklift batteries. By familiarizing yourself with ANSI/NEMA guidelines, ISO norms, UL certifications, IEC regulations, and recycling practices—all these elements contribute towards more sustainable practices that benefit both your company’s bottom line and our planet's health. As you navigate through these complex yet critical landscapes of industry regulations—know that staying informed makes all the difference!