Features of High-Quality Industrial Batteries

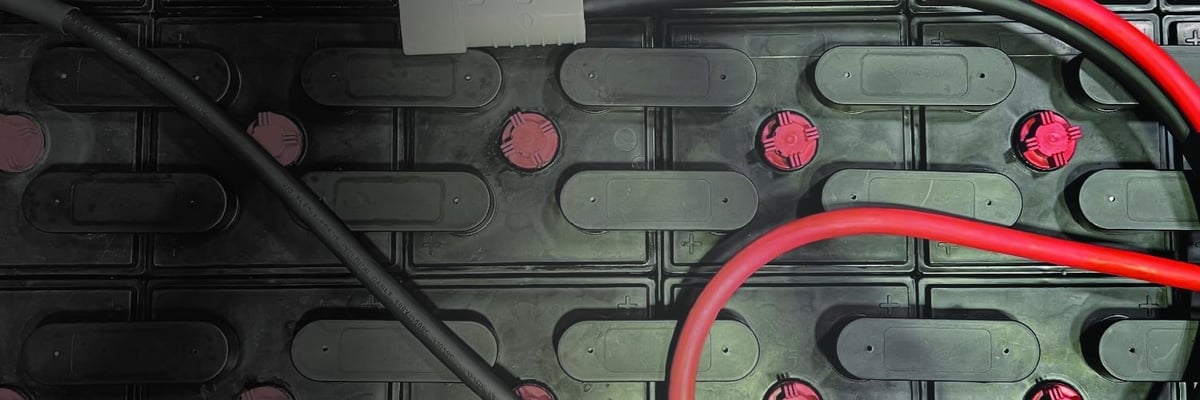

Industrial batteries are the backbone of many manufacturing and logistics operations, powering everything from forklifts to automated guided vehicles. When looking for reliable energy solutions, understanding the features of high-quality industrial batteries is essential. In this article, we’ll delve into what makes an industrial battery top-notch, focusing particularly on forklift batteries, their performance metrics, and how they can impact your operations.

What Are the Key Features of High-Quality Industrial Batteries?

When it comes to selecting industrial batteries, several features stand out as indicators of quality and reliability. These features not only enhance performance but also ensure longevity and safety.

1. Capacity and Energy Density

One of 48 volt flat plate forklift batteries the primary aspects to consider in high-quality industrial batteries is their capacity and energy density.

- Capacity refers to the amount of energy a battery can store, usually measured in ampere-hours (Ah). A higher capacity means longer operational hours between charges.

- Energy density indicates how much energy can be stored in a given volume or weight. This is particularly important for forklift batteries that need to be lightweight yet powerful.

For example, lithium-ion forklift batteries typically have a higher energy density compared to traditional lead-acid counterparts. This means that businesses can enjoy longer run times without needing to compromise on space or weight limitations.

2. Durability and Lifespan

Durability is crucial when investing in industrial batteries. Forklift operations often involve harsh working conditions—think extreme temperatures or rough handling—which can take a toll on battery life.

High-quality industrial batteries are designed with robust materials that resist wear and tear over time. They feature advanced engineering that allows them to withstand shocks, vibrations, and temperature fluctuations far better than standard options.

A good benchmark for lifespan in forklift batteries is around 1,500 cycles for lead-acid types and up to 5,000 cycles for lithium-ion models. Remember that longer lifespans equate to reduced replacement costs over time!

3. Charging Efficiency

Charging efficiency is another critical feature of high-quality industrial batteries.

- Batteries with higher charging efficiency will recharge faster and consume less electricity during the process.

- Fast-charging capabilities are especially important in busy environments where downtime needs to be minimized.

For instance, some lithium-ion forklift batteries can charge up to 80% in just one hour! This rapid turnaround can significantly boost productivity by allowing forklifts more operational time 24 volt flat plate forklift batteries throughout the day.

4. Safety Features

Safety cannot be overstated when it comes to industrial applications. High-quality batteries incorporate several safety features:

- Thermal management systems help prevent overheating during operation.

- Built-in protection mechanisms, such as overcharge protection and short-circuit prevention, safeguard against potential hazards.

Regular maintenance routines should still be implemented; however, these built-in safety features mitigate many risks associated with battery failure.

5. Environmental Impact

As industries shift toward sustainable practices, the environmental impact of battery technology has come into focus.

High-quality industrial batteries often use eco-friendly materials and manufacturing processes that are less harmful to the environment compared to traditional lead-acid options. Furthermore, lithium-ion batteries are more efficient in terms of energy consumption throughout their lifecycle.

Investing in environmentally friendly options not only boosts your company’s sustainability profile but may also offer long-term savings through decreased disposal costs and regulatory compliance expenses.

How Do Forklift Batteries Differ from Other Industrial Batteries?

While many features of high-quality industrial batteries apply across various applications, forklift batteries have unique requirements due to their specific usage patterns.

Heavy-Duty Performance Requirements

Forklift operations demand consistent power output over extended periods while being subjected to heavy loads and repetitive tasks. Therefore:

- Forklift batteries must deliver high discharge rates without compromising performance.

- They need a design that allows for rapid reinvestment back into energy after heavy usage cycles.

This makes specialized technologies like gel cells or lithium-ion systems particularly beneficial as they provide optimal performance under demanding circumstances.

Tailored Charging Solutions

Charging protocols for forklift batteries differ significantly from those used for other devices:

- Many forklifts utilize opportunity charging—this means they may get charged multiple times throughout the day rather than following a strict cycle.

Understanding these specific needs allows businesses to tailor their charging infrastructure accordingly—leading us back again into discussions around efficiency!

Common FAQs About High-Quality Industrial Batteries

- Lithium-ion and lead-acid are popular choices; however, lithium-ion generally offers better performance due to its higher energy density and lower maintenance requirements.

- Regular maintenance like cleaning terminals, ensuring proper water levels (for lead-acid), avoiding deep discharges, and adhering closely to charging protocols will significantly extend your battery's lifespan.

- Look for suppliers with a solid reputation backed by customer reviews; check if they offer warranties; assess their customer support services; inquire about training programs related to battery maintenance!

- Yes! Familiarize yourself with OSHA regulations regarding safe battery operation procedures as well as manufacturer guidelines specific to each type you’re using!

- Frequent trips requiring recharging before shifts end or visible corrosion around terminals are red flags indicating possible failure ahead!

- Yes! Lithium-ion systems often require specific chargers designed for optimal efficiency—using incompatible chargers could void warranties!

Conclusion

In summary, understanding the features of high-quality industrial batteries—specifically when it comes down to choosing fork-lift options—is vital for enhancing productivity while minimizing costs over time! From capacity measurements all through durability assessments right down through environmental impacts—we’ve covered essential knowledge every business owner oughta have at their fingertips before making purchasing decisions! Investing wisely means considering not just immediate needs but also future ramifications based on evolving technologies within this ever-changing landscape! So whether you’re upgrading existing units or starting fresh—be sure these crucial elements make it onto your checklist!